UHMW or How to Extend the Life of Your Equipment

While Reducing Your Maintenance Costs

| |

|

Michel Bergeron, Technical Advisor

With more than 12 years as part of the PolyAlto family, Michel is an invaluable source of plastics solutions knowledge.

email: michel.bergeron@polyalto.com

|

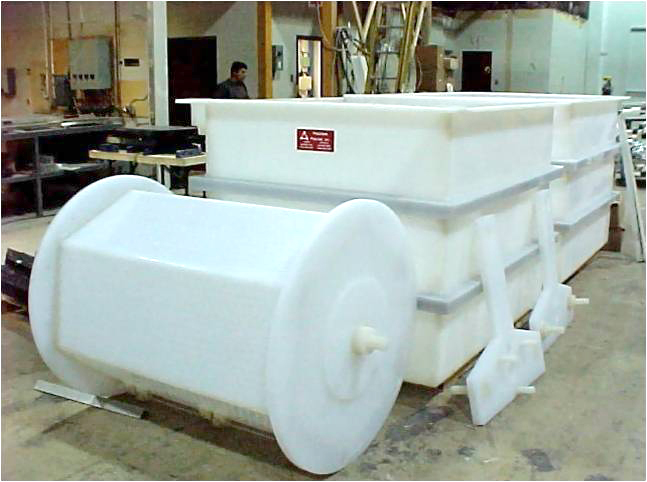

Replacing a component with a high-performance plastic product like UHMW (ultra-high molecular-weight polyethylene) is increasingly common. Such parts often cost less and perform better than a similar metal or wood product.

In fact, plastic offers significant advantages: corrosion-resistant, easy to process and lightweight, to name but a few.

Part of the polyethylene family, UHMW plastic has outstanding abrasion resistance (10 times higher than carbon steel). This makes it ideal for applications that require greater resistance to

premature wear due to abrasion, shocks and corrosion.

UHMW offers:

- a friction coefficient substantially lower than nylon or acetal;

- high impact resistance (even at low temperatures); and

- excellent corrosive chemical tolerance.

Polyethylene plastic components require little maintenance, reduce noise levels and extend the life of your equipment. They can also be easily machined to meet your needs and are 100% recyclable.

Contact our experts to select the right plastic for your application. Optimize your performance, increase the useful life of your machinery and minimize the maintenance your equipment requires.

Main advantages:

- Thermoplastic highly resistant to abrasion (7 times higher than regular steel)

- Very low friction coefficient

- Highly resistant to impact and fatigue

- Keeps its physical properties even at low temperatures (-80° c)

- Excellent chemical resistance

- In its natural formulation, it is approved by the FDA-USDA and Agriculture Canada

(offered in colour pigments approved by the FDA)

- 0.01 moisture absorption

- Several options (NATURAL WHITE-REPROCESSED BLACK-ANTISTATIC-T88 [T-88-2 WELDABLE] POLYSTEEL-QUICKSILVER-CERAM-P

- Available in RODS-SHEETS-BANDS-TUBES AND PROFILES

Applications for which UHMW plastics surpass several

Applications for which UHMW plastics surpass several

other materials, including metals:

- Conveyor wear liners

- Snowmobile drive wheels

- Guide rails

- Bearings

- Paper machine vacuum box covers

- Chute cladding

- Drain pipes for liquids

- Any other component that requires maximal impact and abrasion resistance and a low friction coefficient

Polyethylene distributed by Groupe PolyAlto.

- Reprocessed UHMW Durapro®

- UHMW Tivar® Eco

- UHMW Tivar® 88

- UHMW Tivar® 1000

- UHMW Tivar® Ceram P®

- UHMW Tivar® Cleanstat™

- UHMW Tivar® Dock Guard

- UHMW Tivar® DryslideMD

- UHMW Tivar® Esd/ec

- UHMW Tivar® H.O.T.

- UHMW Tivar® Hpv

- UHMW Tivar® MD

- UHMW Tivar® Polysteel

- UHMW Tivar® UV-resistant

- UHMW Quicksilver®